Wickelmaschinen für ein perfektes Ergebnis

Realisieren Sie Ihre Maschine und Produktionsanlage mit den besten Wicklern, Modulen und Komponenten der Wickeltechnologie.

Von Supertek erhalten Sie von der Komponente bis zur gesamten Produktionsmaschine alles aus einer Hand.

Hochpräzise Wickeltechnologie für Feinstdraht, Flachdraht, Bänder, Folie, Filament, optische oder thermoplastische Fasern.

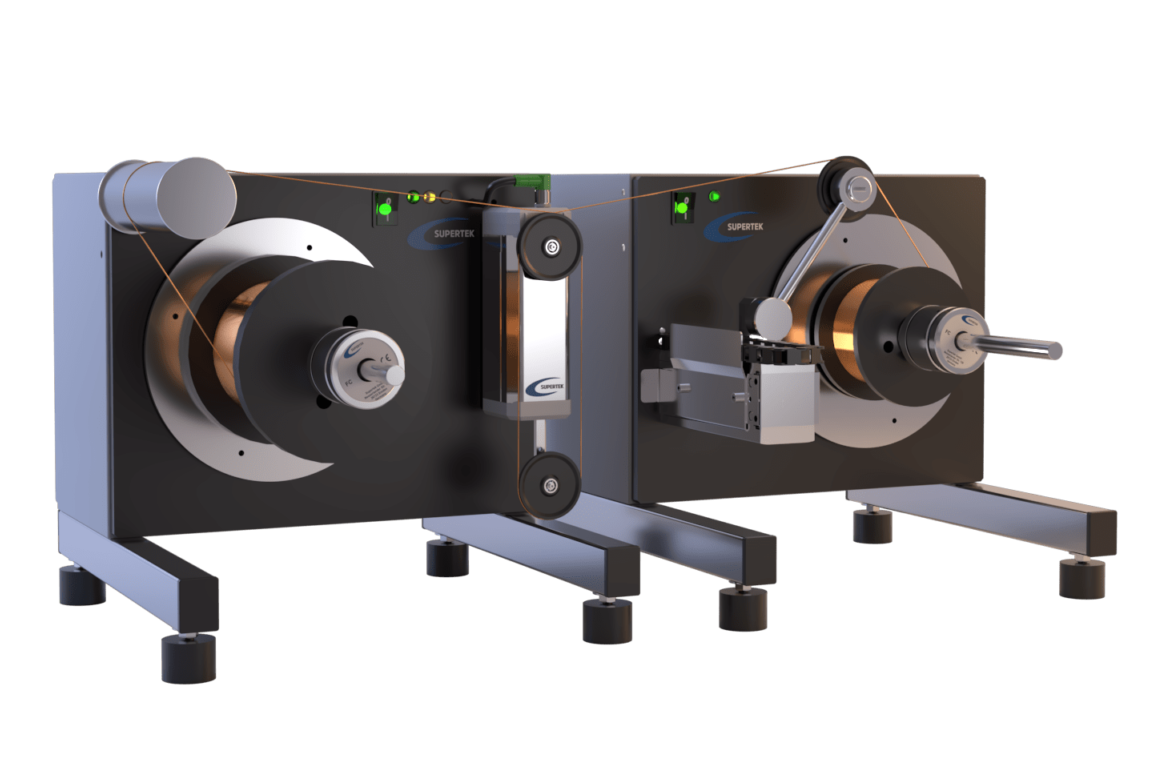

Wickler mit innovativen Antriebs- und Verlegesystemen

Entdecken Sie unsere Wicklermodule der ED-, MW- und SW-Klasse für Wickelmaschinen: Spulen mit elektronischen Verlegesystemen für präzise und lagenreine Wicklungen. Die ED- und MW-Klasse sind mit Antriebssystemen ausgestattet, die eine Welle zur Aufnahme der Spulen besitzen. Die Wickler der SW-Klasse sind wellenlos und verfügen über eine innovative Spulenaufnahme mit automatischer Spanneinheit für einen perfekten Rundlauf. Auch ein automatischer Spulenwechsel ist möglich. Zum geradlinigen Spulen von Flachdraht verfügen die Wickler der MW- und SW-Klasse über ein Verlegesystem, das den gesamten Spulenantrieb linear bewegt.

Wickler der ED-Klasse

Tischwickler für kleine Spulen, dünne Drähte und feine Fasern für das Ab-, Auf- und Umspulen. Präzise Regelung der Zugspannung und genaue Wicklungen beim Aufspulen mit elektronischer Verlegeeinheit.

- Elektronische Verlegeeinheit

- Spulenaufnahme mit Welle

- Spulengewicht bis 5 Kg

- Verlegerbreite bis 250 mm

- Spulendurchmesser bis 260 mm

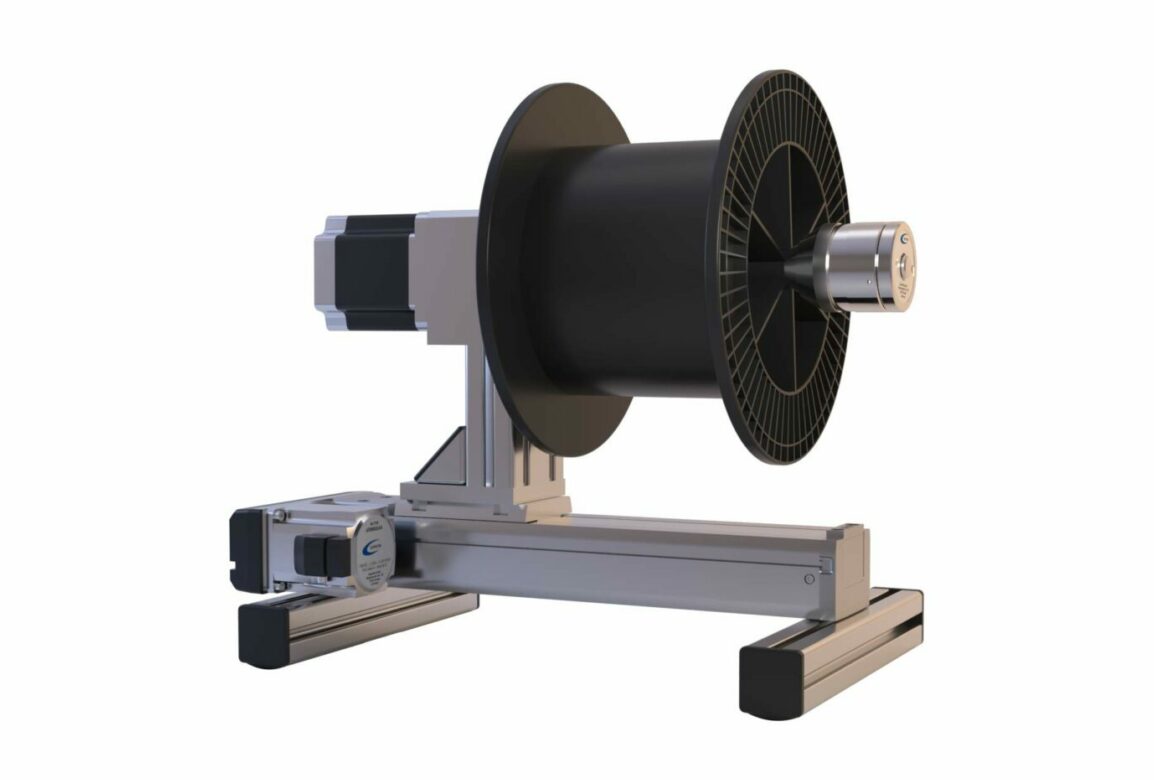

Wickler der MW-Klasse

Die professionelle Lösung zum Ab-, Auf- und Umspulen von Spulen für Rund- und Flachdrähte, Folien und Fasern. Automatisch travesierende Spule zum Verlegen von präzisen Wicklungen.

- Automatisch traversierende Spule

- Spulenaufnahme mit Welle

- Spulengewicht bis 10 Kg

- Verlegerbreite bis 250 mm

- Spulendurchmesser bis 360 mm

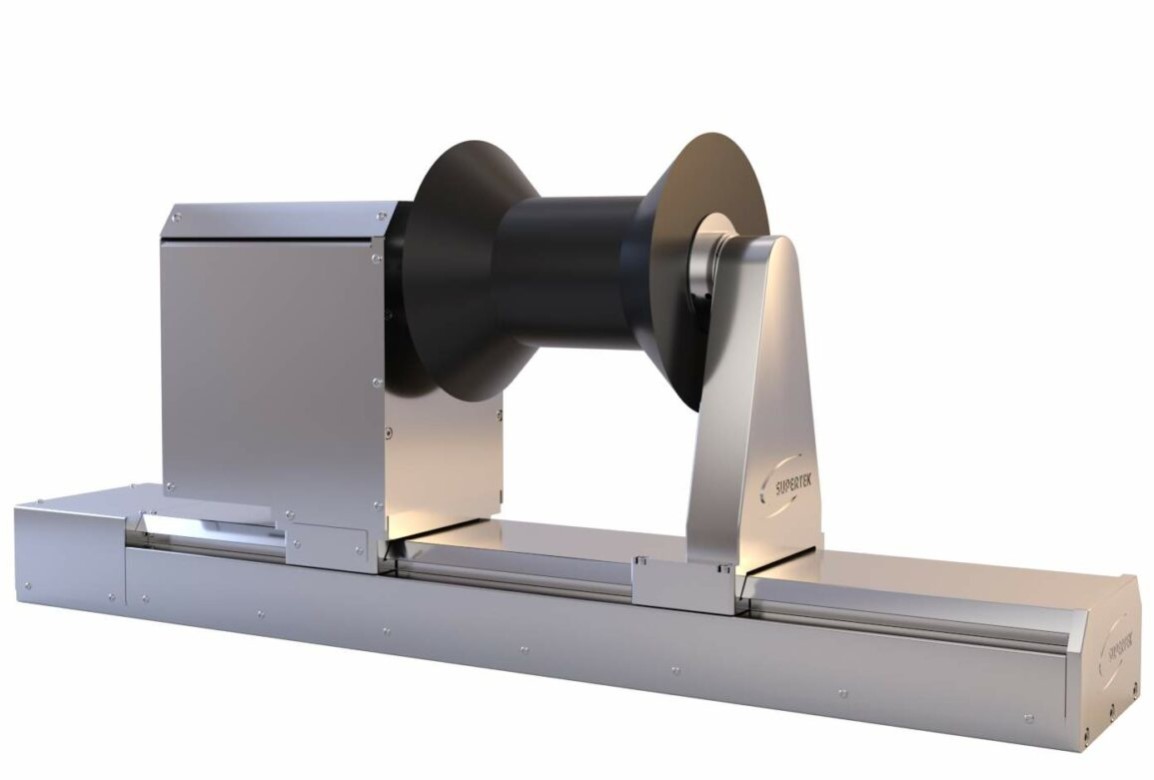

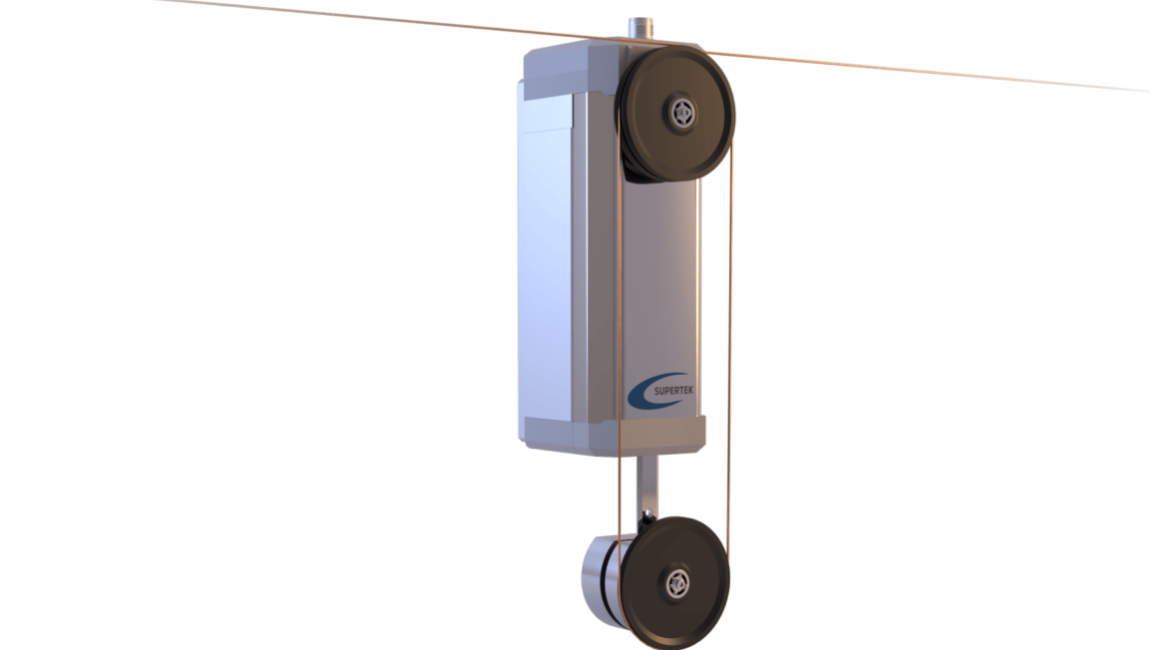

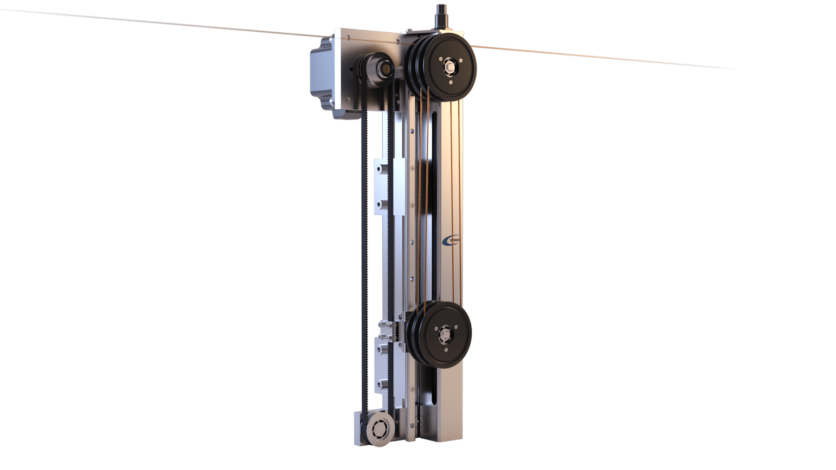

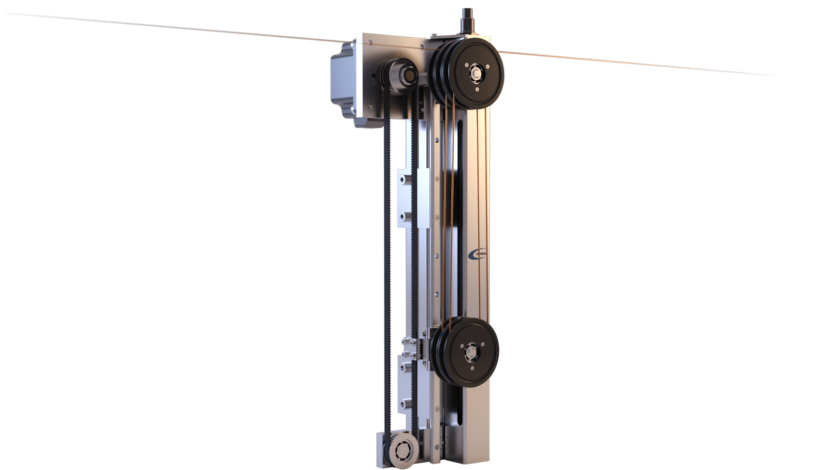

Wickler der SW-Klasse

Die hochpräzise Lösung für das automatisierte Abspulen, Aufspulen und Umspulen verschiedenster Spulenformen, Rund- und Flachdrähte, Folien, Bänder und Fasern. Automatisch traversierende Spule mit gegenüberliegender Spanneinheit.

- Automatisch traversierende Spule

- Automatische Spanneinheit

- Automatischer Spulenwechsel optional

- Spulengewicht bis 25 Kg

- Verlegerbreite bis 325 mm

- Spulendurchmesser bis 460 mm

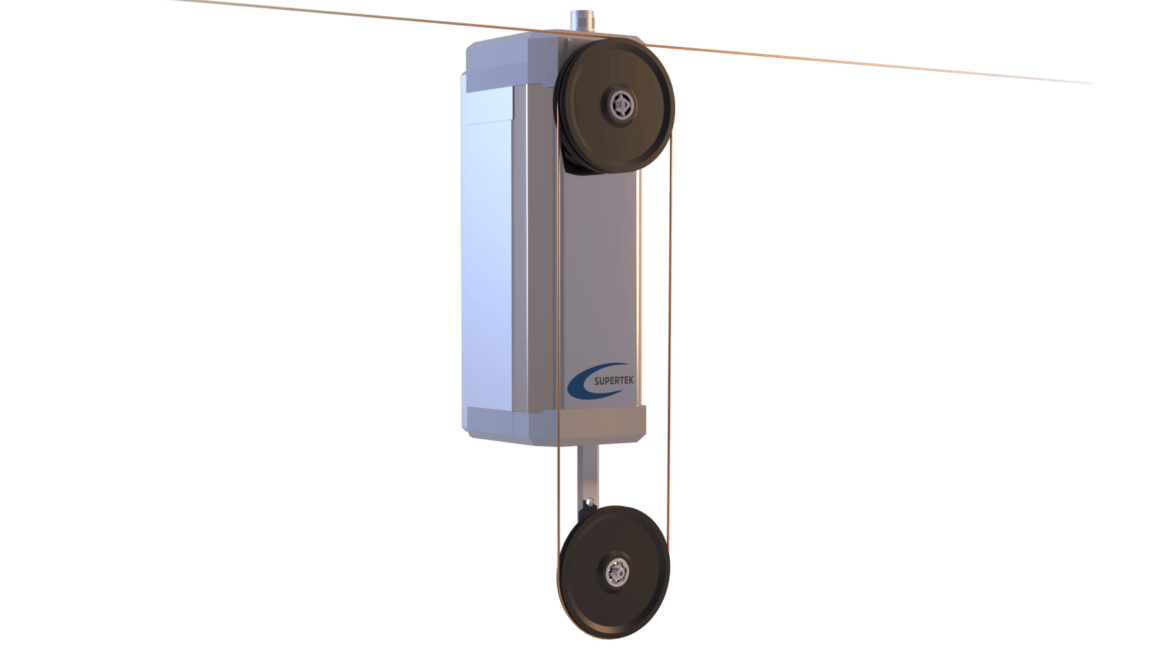

Optimale Zugspannung für feinste Drähte und optische Fasern

Die patentierten elektromagnetischen Tänzer sorgen für die exakte und feinfühlige Regelung der Drahtspannung und Faserspannung.

Elektromagnetischer Tänzer EDR 10

Der elektromagnetische Tänzer EDR 10 für hochpräzise Zugkräfte 2 mN bis 1000 mN

- Tänzerkraft 4 mN bis 2000 mN

- Patentierte elektromagnetische Krafterzeugung

- Konstante Draht- und Fadenspannung unabhängig der Tänzerlage

- Hochdynamisch

- Krafteinstellung analog oder digital in 1 mN Schritte

- Verwendung für sensible Fasern und Feinstdrähte

Elektromagnetischer Tänzer EDL 60

Der elektromagnetische Tänzer EDL 60 für hochpräzise Zugkräfte 10 cN bis 600 cN

- Tänzerkraft 20 cN bis 12 N

- Patentierte elektromagnetische Krafterzeugung

- Konstante Kraft unabhängig der Tänzerlage

- Hochdynamisch

- Krafteinstellung analog oder digital in 1 mN Schritte

- Verwendung für Draht, optische Fasern und Glasfasern.

Elektromagnetischer Tänzer EDL 60G

Der elektromagnetische Tänzer EDL 60G für präzise Zugkräfte 100 cN bis 900 cN

- Tänzerkraft 200 cN bis 18 N

- Patentierte elektromagnetische Krafterzeugung zzgl. Gewicht

- Konstante Kraft unabhängig der Tänzerlage

- Krafteinstellung analog oder digital in 1 mN Schritte

- Verwendung für Bänder, Fasern und Drähte

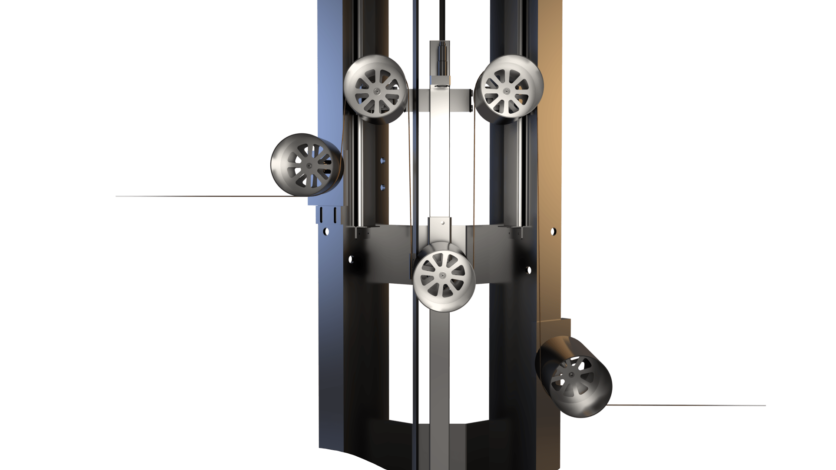

Tänzerspeicher und Zugkraftregelung

Zum Regeln der Zugspannung und zum Speichern von Drähten, Fasern und Bändern.

Elektronischer Lineartänzer EBL 100

Der elektronische Lineartänzer EBL 100 mit viel Kraft und großem Tänzerhub bis 10 N

- Tänzerkraft bis 20 N

- Elektronische Krafterzeugung

- Krafteinstellung analog oder digital

- Verwendung für Drähte und Folien

- Berührungslose Positionsmessung

Elektronischer Lineartänzer EBL 500

Der elektronische Lineartänzer EBL 500 mit viel Kraft und großem Tänzerhub bis 50 N

- Tänzerkraft bis 100 N

- Elektronische Krafterzeugung

- Krafteinstellung analog oder digital

- Verwendung für Drähte und Folien

- Berührungslose Positionsmessung

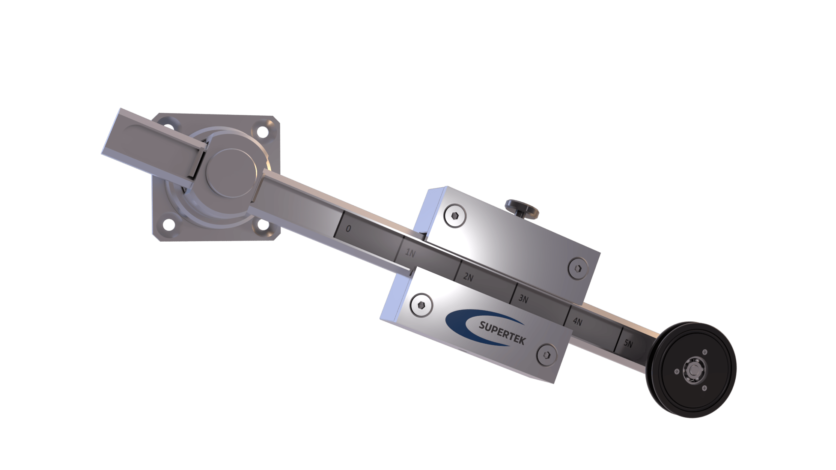

Mechanischer Drehtänzer GDR 100

Der mechanische Drehtänzer GDR 10 N für robuste Anwendungen.

- Tänzerkraft bis 20 N

- Zugkraft bei einer Umschlingung bis 10 N

- Mechanische Krafterzeugung

- Krafteinstellung manuell über Gewicht

- Berührungslose Positionsmessung

Hard- und Software für effiziente und präzise Wickelergebnisse

Die besten Komponenten der Wickeltechnologie zum automatisierten Spulen.

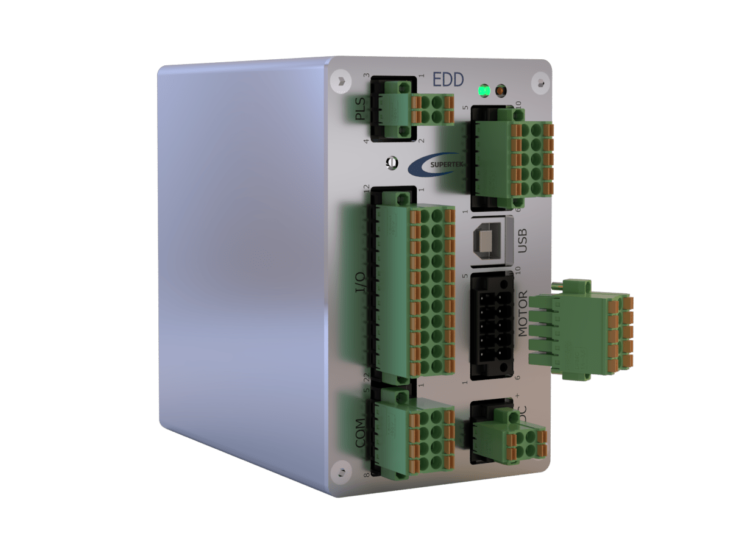

Tänzerregler EDD

Der Tänzerregler EDD bietet alle Funktionen für die Zugkraft- und Tänzerlagenregelung.

In Kombination mit einem elektromagnetischen Tänzer ist der Tänzerregler die präziseste Zugkraftregelung weltweit.

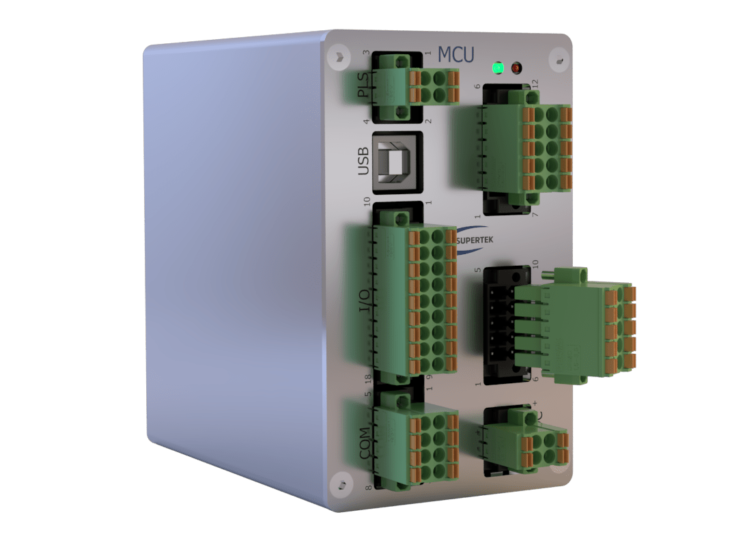

Winding Controller MCU

Der Winding Controller MCU ist die prozessorgesteuerte Echtzeitlösung zur hochpräzisen Verlegung beim Aufspulen.

Mit der integrierten Maschinen- und Verlegesteuerung werden beste Wickelergebnisse erzielt. Der winding controller bzw. Wickelrechner enthält alle leistungsfähigen Softwarefunktionen zum Wickeln und Umspulen.

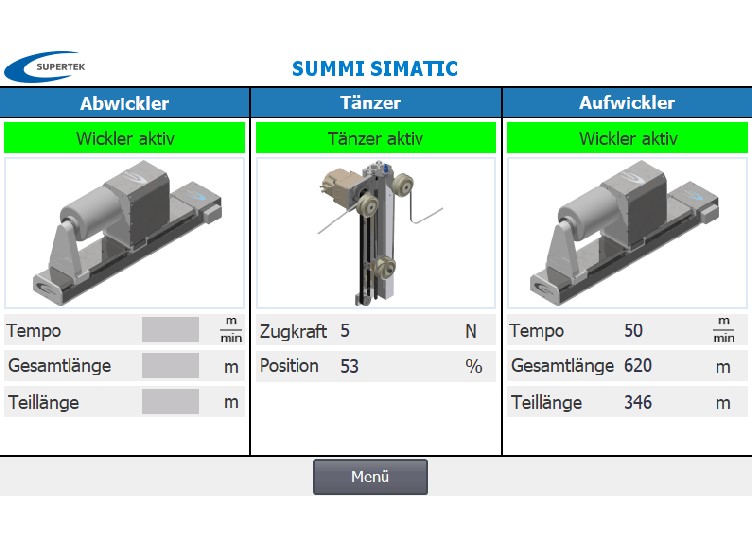

PC-Software SUMMI pro

Die Software SUMMI pro ist eine HMI-Anwendungssoftware für Touchpanel-PCs, Notebooks, und Tablets mit Windows Betriebssystem.

SUMMI pro wird zum Bedienen und Beobachten von Wickelprozessen eingesetzt. SUMMI pro ist ideal für Linearwickler, Wickelautomaten oder Umspulmaschinen.

Bedienen und Beobachten in der Wickeltechnologie

Die bedienerfreundlichen HMI-Panels von Supertek.

Bedieneinheit CMC

CMC ist eine Bedien- und Steuereinheit für Komponenten und kompakten Maschinen der Wickeltechnologie. Mit der Bedieneinheit kann der Tänzerregler EDD oder der winding controller MCU parametrisiert und bedient werden.

Bedienpanel MTP SUMMI-PC

Das Bedienpanel für Abwickler, Aufwickler und Umspulmaschinen mit Touch-PC.

Plug and play mit der PC-Software SUMMI pro. Einfache Kommunikation mit Komponenten der Wickeltechnologie, u.a. Tänzerregler EDD und winding controller MCU.

Bedienpanel MTP SUMMI-SIMATIC

Die komfortable HMI von Supertek für die Industrie. Mit SIMATIC HMI Panel von Siemens, sowie Funktions- und Melde- Tasten für die automatisierte Maschinensteuerungen. Professionelle Visualisierung und einfache Bedienung, unterschiedlichster Maschinen. Mit der Software SUMMI-SIMATIC ideal als HMI für Wickelmaschinen.

Spulen-Scanner und Positions-Scanner

Ideale Sensorik für das kontrollierte Spulen und die perfekte Wicklung!

Professionelle 3D-Scannung der Spule und Detektion der Position von einzelnen Drähten und Fasern.

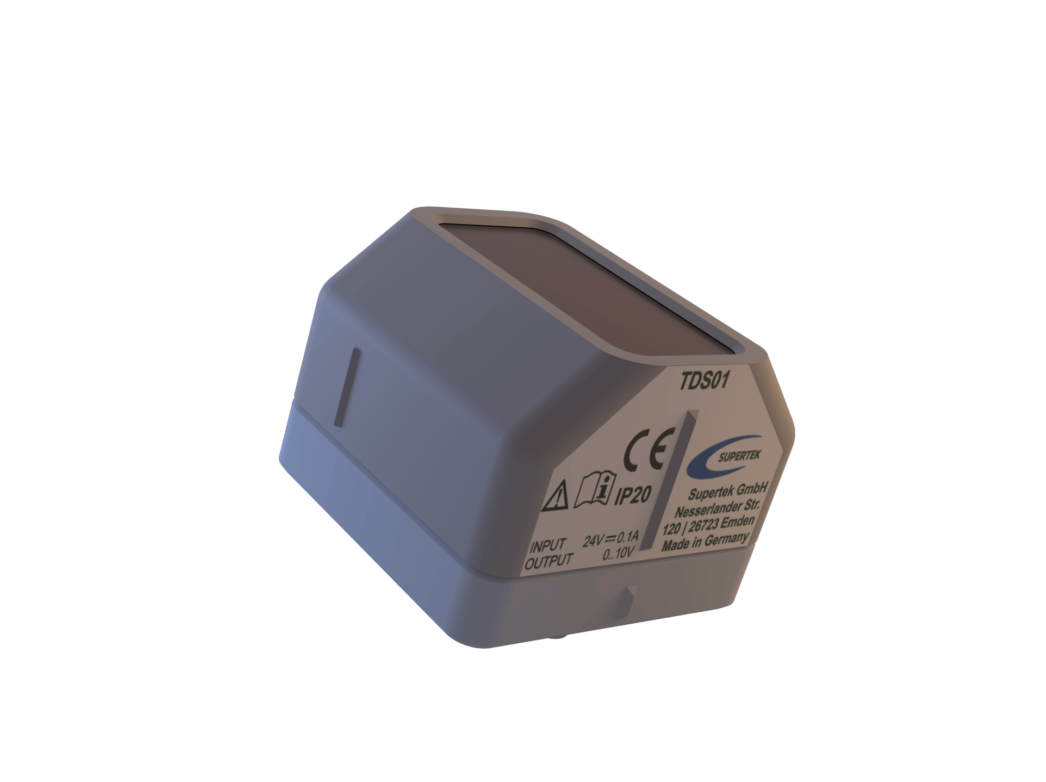

Spulenscanner TDS 3D

Der 3D-Spulenscanner scannt die Spulengeometrie während des Spulens in Echtzeit.

Mit dem Spulenscanner werden die Flansche einer Spule und das Wickelbild automatisch erkannt. In Kombination mit dem Winding Controller MCU werden perfekte Wickelbilder auch auf konischen Spulen erzeugt.

Leichtläufige Umlenkrollen

Von Supertek erhalten Sie die passenden Führungsrollen für feinste Drähte, optische Fasern, Filamente, Flachdraht oder Bänder.

Nutzen Sie die professionellen Rollen von Supertek für reibungslose Wickelprozesse.